Chapter 1: What is Fuel Tanker Trailer?

Chapter 2: Why does the Fuel Tanker Semi Trailer Have Several Compartments?

Chapter 3: Materials for Making Fuel Tanker Trailer

Chapter 4: Accessories for Fuel Tanker Trailer

Fuel tanker trailer is mainly used to transport large amount of liquid etc. Because of the wide variety of liquefied loads, there are many different models of this fuel tanker trailer.

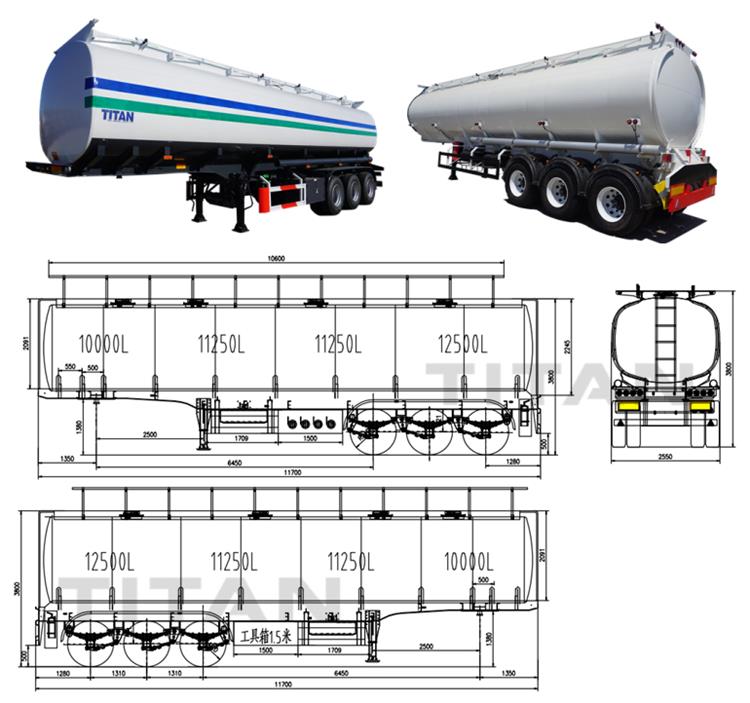

Fuel tanker trailer for sale tank trucks designed to carry one load have only one single compartment, while tank trucks carrying multiple loads have multiple internal partitions in the tank body.

The primary differentiating factors of a Fuel tanker trailer for sale include the shape of the tank, the type of load the trailer will carry and its size. Other differentiating factors include refrigeration capacity, pressurization capacity and acid resistance.

Fuel Tanker Trailer for Sale | 45,000 Ltr Capacity Tank - TITAN Vehicle Co., Ltd

Fuel Tanker Trailer for Sale | 45,000 Ltr Capacity Tank - TITAN Vehicle Co., Ltd

The most common tank trailer you see on the road is the fuel tanker trailer. This trailer is used to transport gasoline, diesel and benzene. It is also used to transport certain flammable and explosive liquids.

Gasoline and diesel are used for standard cars and other types of vehicles. Therefore, most fuel tanker trailers for sale have more than one compartment. Why does the fuel tanker semi trailer have several compartments? There are mainly the following reasons:

Efficiency principle: A fuel tanker trailer for sale has different compartments and can transport different liquids at the same time. This reduces transportation costs and saves fuel as the number of journeys is reduced to one.

Transporting different liquids on different fuel tanker trailers for sale is unconventional and inefficient. The fuel tanker trailer for sale with a large compartment can transport different grades of gasoline at one time. A gas station can accept all the oil products needed at one time.

Guaranteed stability: When the trailer climbs a slope, the liquid in the tank will slosh in all directions. If the tank truck is heavily loaded, this shaking can cause a change in the center of mass.

Then, this will cause the axle load to change, which will affect the stability of the truck and fuel tanker trailer for sale. This instability may cause the folding knife of the fuel tanker trailer for sale (the articulated vehicle fails to bend) or roll over. Models using multiple compartments can reduce axle load changes, thus maintaining trailer stability.

Fuel Tanker Trailer for Sale | 45,000 Ltr Capacity Tank - TITAN Vehicle Co., Ltd

Fuel Tanker Trailer for Sale | 45,000 Ltr Capacity Tank - TITAN Vehicle Co., Ltd

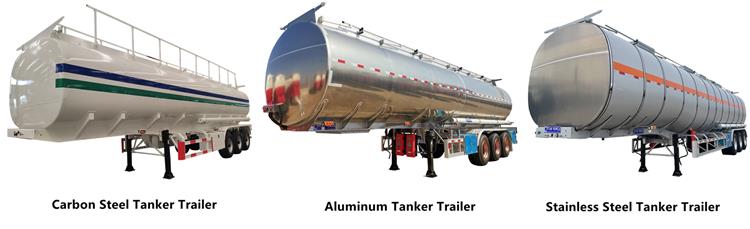

Let's take a look at the different materials used to make fuel tanker trailer for sale. Trailer manufacturers generally use carbon steel or stainless steel and aluminum alloys to manufacture different fuel tanker trailers for sale.

Each material has its advantages and disadvantages. Let's take a look at the pros and cons of each material.

Carbon steel and stainless steel, the advantages of using carbon steel and stainless steel trailers include:

Steel has high strength and is not easily damaged. Steel is more competitively priced, so steel is more popular in developing countries. Carbon steel is easier to weld. Steel is less prone to stress cracking, but this is very common on aluminum alloys. Stainless steel It can prevent rust and can transport food.

The disadvantages of using carbon steel are:

Carbon steel needs to be galvanized or coated on the surface to prevent rust. It is denser than aluminum alloy.

The advantages of using an aluminum tanker trailer are:

Lighter than vehicles using steel. Aluminum tanker trailers can transport more liquid loads.The aluminum tanker trailer is safer and stronger. Aluminum alloy material is rust-resistant, so it will not contaminate liquids during transportation.

Some disadvantages of aluminum alloys are:

The strength of aluminum alloy is almost half of the strength of steel. It is very easy to have stress cracks. It is very difficult to weld aluminum alloy. The price of aluminum alloy is more expensive than steel

The type of material used in a Fuel tanker trailer determines its price and load-carrying capacity. An aluminum tanker trailer may be light enough to resist rust, but it has low strength and a high price.

When choosing between these two materials, you must consider the end use and budget of the aluminum tanker trailer. If you need a fuel tanker trailer with high load capacity and low price, maybe a steel trailer is your best choice.

The fact that aluminum alloys are lighter and less strong than steel does not mean that aluminum tanker trailers are weak. The aluminum tanker trailer has sufficient carrying capacity to transport large quantities of fuel.

Fuel Tanker Trailer for Sale | 45,000 Ltr Capacity Tank - TITAN Vehicle Co., Ltd

Fuel Tanker Trailer for Sale | 45,000 Ltr Capacity Tank - TITAN Vehicle Co., Ltd

Tank bodies, Heads and Barrels

Fuel tanker trailers come in different shapes, including round, oval, and rectangular. Their center of gravity to height ratio is 1:0.79:0.65. Large oil tank trucks are all oval and round rectangles because of the need for stability.

The tank body of the tank trailer includes a head and a tank. The tank barrel is wound and welded by steel plate. The head is integrated (one piece) by the spinning stamping process.

The process involves continuous partial stamping at a specific temperature. In order to ensure that the tank and head are welded accurately, the roundness tolerance should be less than 3mm.

Oil Baffle

In order to reduce the sloshing of the liquid in the fuel tanker trailer, all spaces in the tank have oil baffles. A longitudinal oil baffle is arranged along the longitudinal axis of the tank to reduce lateral sloshing of the liquid in the tank.

A transverse oil baffle along the cross-sectional direction can slow down axial liquid sloshing in the tank.

The transverse oil baffle has manholes in each plate, the diameter of which is probably not less than 550mm. These dimensions are necessary for easy maintenance of the board.

In order to improve the effect of the horizontal baffle, open two or more manholes at the baffle. Manholes should be staggered in the first compartment of the cylinder.

Fuel Tanker Trailer for Sale | 45,000 Ltr Capacity Tank - TITAN Vehicle Co., Ltd

Fuel Tanker Trailer for Sale | 45,000 Ltr Capacity Tank - TITAN Vehicle Co., Ltd

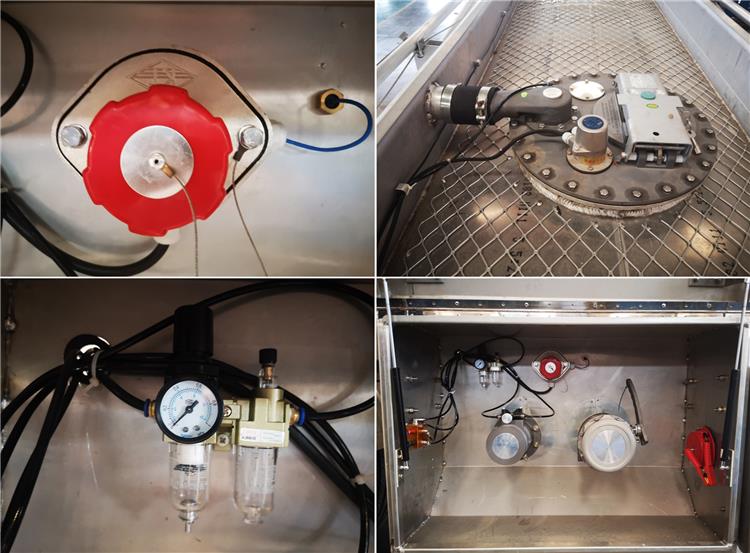

Fuel Tanker Trailer Manhole Cover, Breather Valve and Anti-Leak Sensor

The manhole cover just refers to the trailer manhole cover, as shown in the picture below. There are some important parts on the cover that you should be aware of to keep the fuel tanker trailer safe.

One of the important parts of the manhole cover is the breathing valve, also known as the safety valve. The function of this valve is to automatically adjust the pressure in the fuel tank.

This helps keep the pressure within a certain range. The safety valve protects the oil tank and reduces the volatilization loss of volatile oil.

The breathing valve body is made of nickel-chromium stainless steel. All other parts are constructed of stainless acid-resistant steel to resist rust.

All compartments of small and medium tanks have a breather valve. Large tanks, on the other hand, have breather valves in each compartment.

Anti-leak Sensor

The anti-leakage sensor is an alarm installed on the manhole cover. Whenever the level of liquid in the tank changes rapidly, the sensor emits a sound or noise.

When the liquid reaches the correct level, the whistle or alarm stops. In this case the sensor acts as a fill alarm. Additionally, the whistle stops when the fuel tanker trailer drain is emptied of fluid.

Oil Vapor Recovery Valve

The oil and gas in the volatile oil can be recovered to the oil tank to prevent the oil and gas from leaking. Other vapor recovery units are used to concentrate and reuse vapors.

Oil Piping System

The system consists of several valves including bottom valve, oil vapor recovery valve and fuel outlet valve.

Bottom Valve

The bottom valve is generally installed at the outlet of the fuel tanker trailer. If there is a collision in an accident, the valve can cut off the pipeline within 5 seconds. This ensures the safety of goods and people inside the vehicle.

The quick shutoff also prevents leaks and explosions in the event of an accident. This quick shutoff saves lives and prevents loss of transported fluids.

For their own safety, fuel tanker trailer drivers are advised to check the other valves before loading the trailer.

Fuel Tanker Trailer for Sale | 45,000 Ltr Capacity Tank - TITAN Vehicle Co., Ltd

Fuel Tanker Trailer for Sale | 45,000 Ltr Capacity Tank - TITAN Vehicle Co., Ltd

Fuel Outlet Valve

This valve is used to quickly unload the fuel tanker trailer. Its internal structure complies with fluent mechanics to keep internal pressure to a minimum during periods of high flow.

The special construction used in the fuel outlet valve helps ensure no oil leaks when the fitting is removed.

Top or Bottom Loading

There are two ways to load fuel or liquid in the fuel tanker trailer. Fuel or liquids can be loaded from the top or bottom. Each way has its pros and cons.

Top Loading: Loading fuel or liquids is unsafe and dangerous. Gasoline evaporates into the atmosphere when loaded from the top. Vapors or fumes can increase the risk of an explosion at a gas station.

In addition, boil-off gas is the loss of the total volume of the cargo. Top loading is also a hazard to workers and should be avoided at all costs. Also, top loading is time consuming.

Bottom loading: This method is recommended for all types of fuel oil and liquid cargoes. Fast loading, safe and efficient. Gasoline gas is still circulating internally.

Bottom loading has no risk of explosion and is therefore safe for workers.