Crude oil tanker trailer is mainly used to transport gasoline, diesel, oil, gasoline, motor oil, etc., mainly for long-distance transportation. Crude oil tanker trailer can load 30000-60000 liters.

When we load and unload, we will definitely use the oil and gas recovery valve, which can recover the excess volatile oil and gas, not only to reduce waste but also to ensure safety.

Crude Oil Tanker Trailers for Sale | Crude Oil Tank Trailers for Sale | Oil Tank 40,000 Ltr

Crude Oil Tanker Trailers for Sale | Crude Oil Tank Trailers for Sale | Oil Tank 40,000 Ltr

Tare Weight (semi trailer): About 8000-12800kg

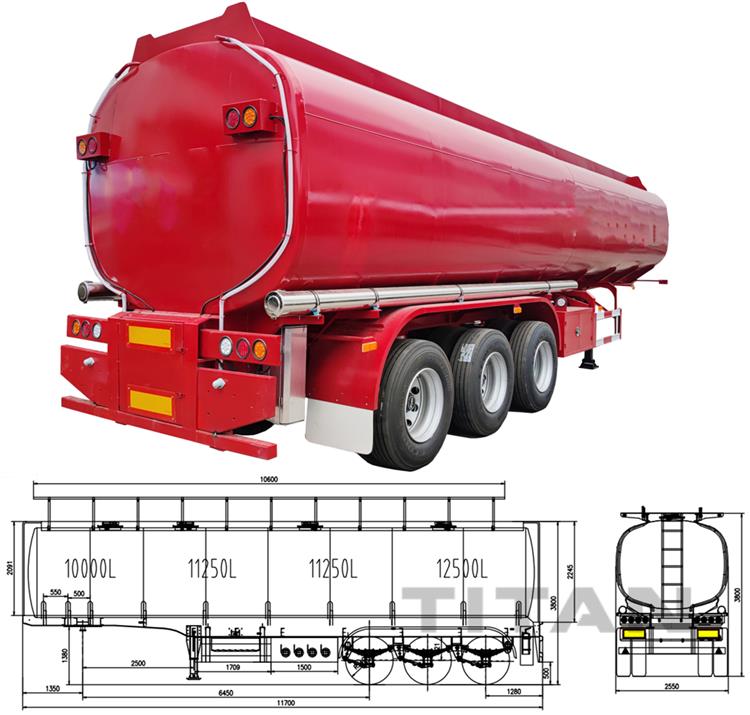

Total volume: 40,000 liters

Tank Body Material: 5mm or 6mm/Q235 carbon steel

End plate: 5mm or 6mm/Q235 carbon steel

Manhole Cover: Carton steel

Discharging Valve: Diameter is 3 or 4 inch

Compartments: 4 Compartsments

Discharging Pipe: 4 inch rubber hose,2pcs,6m/each

Cat Walk: With (common model or special design)

Main beams: Welded design or special design I beam, connected by bolts and nuts Q345 carbon steel material

Axle: 3 axles,12T/13T/16T,BPW/ FUWA/ TITAN brand

Landing Gear: JOST(D200T) or China brand 28T

Kingpin: JOST 2.0 or 3.5 inch bolt-in king pin

Suspension: Mechanical suspension /Germany or America type /Air Suspension

Leaf Spring: 90(w)mmx13(thickness)x10layers or 10mm x12mmx12 layers

Pneumatic Braking System: WABCO RE 6 relay valve; T30/30+T30 Spring brake chamber(TKL brand); 45L air tank

Rim: 9.00-22.5/8.00-20/8.5-20 Chinese brand

Tire: 12.00R22.5/315.80R22.5/11.00R20/12.00R20 brand can be optional

ABS: Optional

Painting: Sandblasted, anti-rust chassis surface is available with 1 layer of anticorrosive primer and 2 layer of top coats.

Accessories: One standard tool box

Shipping Terms: By bulk cargo, RORO or 40HQ containers

Suspension system (rigidity): Transfer load and absorb vibration.

Axle and wheel hub system: Single, two and three axle assemblies with the same structure are installed under the suspension system. The tire and rim assembly are fastened to the wheel hub with tire bolts to support the weight of the entire vehicle.

Landing leg lifting mechanism: In order to make the oil tank trailers able to park reliably after being separated from the tractor, two outriggers, linked or single-acting, are provided at the front end of the frame. It is composed of a screw drive mechanism, a bevel gear drive mechanism, a two-speed reduction box, a transmission rod, and an operating handle.

When the handle is pushed in, it can be raised and lowered at a high speed by turning, and when the handle is pulled out, it can be raised and lowered at a low speed by turning. When the landing legs touch the ground, they can only be raised and lowered in low gear.

Through this video, you can learn about different types of fuel tanker trailers, as well as the process, testing, packaging and customer feedback, etc.